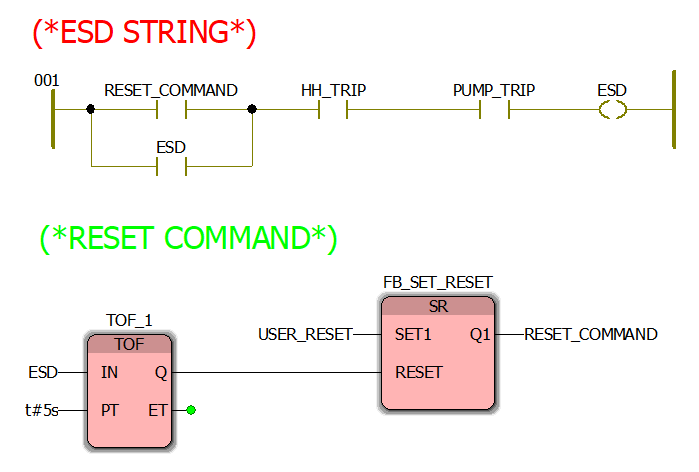

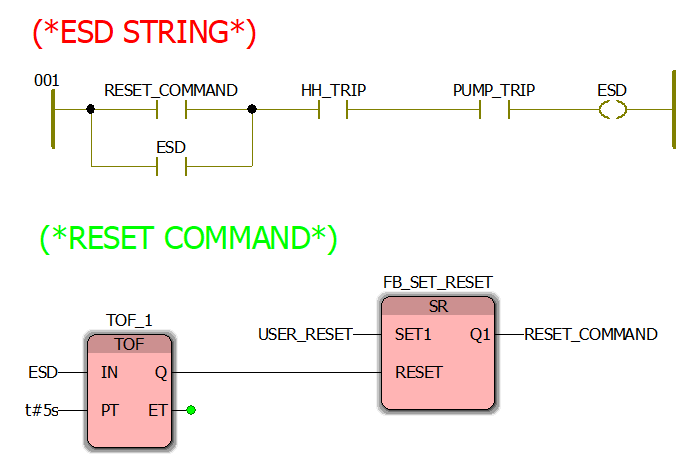

Here is a sample PLC logic for ESD string and reset logic in Yokogawa STARDOM using Logic Designer.

Here are the highlights of the PLC logic execution. This is a fail safe logic, that is, the “ESD” will always stay energize when there is no ESD state.

1) In rung 001, under normal circumstance the following tags will be in the following state.

a) RESET_COMMAND – De-energize

b) HH_TRIP – Energize

c) PUMP_TRIP – Energize

d) ESD (coil) – Energize

And in the function block (TOF_1 and FB_SET_RESET), these are the states of the tags.

a) USER_RESET – De-energize

b) RESET_COMMAND – De-energize

2) For instance if the HH_TRIP were to de-energize, that condition will de-energize the ESD coil. And therefore causing and ESD state.

3) Once the HH_TRIP is energize again (return to normal state), the ESD coil will remain de-energize.

4) When the user energize the USER_RESET tag, the FB_SET_RESET (SR) function block wil energize the RESET_COMMAND tags and therefore energizing the ESD coil. This will set the rung 001 aka ESD string (reset the ESD logic) back to its normal state.

5) At the same time, when the ESD coil is energized, the TOF_1 timer begins to count up to 5 seconds. When the 5 seconds timer expires, the TOF_1 timer function block will energize the Q which energizes the RESET in the SR function block. And this RESET in the SR function block will set the RESET_COMMAND to de-energize.

Step 5 is necessary in cases where the HMI does not have a momentary push button where the energize command to a tag is held for a few seconds before de-energizing it.

I hope this helps!

Happy programming!