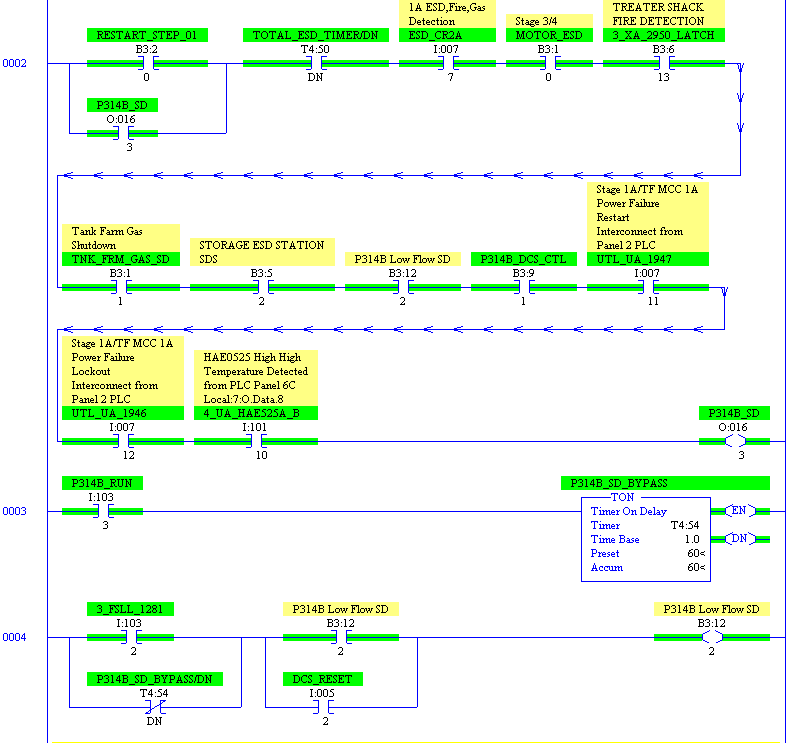

The logic below demostrates a few things.

Firstly, it shows an ESD string in Rung 0002.

The second part of the logic is what I want to chat about today.

It is written to allow the pump to start and build flow (and hence energizing the flow switch FSLL).

Under normal operations, the shutdown coil (in Rung 4) will be energized (fail safe logic) and will be held energized by low low flow switch.

As the pump starts at least for the first 60 seconds, rung 4 is held energize by the Normally Close (NC) shut of the timer (XXXXXX/DN)

Once the timer (TON) is done, the NC shut (XXX/DN) wil de-energize as the TON is completed. But by then, the flow switch (FSLL in Rung 3) should be energized as there is flow.

One more thing to note here is that this logic also takes care of pump running but with empty pipe (no flow). After 60 seconds (TON) is expired, and if there is still no flow (FSLL in Rung 0004 not energized), then the shutdown rung will be de-energized.

The last thing to note is that of a reset function.

The pump must be started and running, only after that a reset button can be pressed to keep the pump running (shutdown coil energized).