Abnormal Situation Management in Small Scale HMI

This article outlines basic ASM guideline that should be applied to a HMI at a minimum (for a small scale HMI development).

This article outlines basic ASM guideline that should be applied to a HMI at a minimum (for a small scale HMI development).

-

- OMG!! How did we got here??!

The core of ASM problem is what we have referred to as the “Paradox of Automation”. As part of human evolution, we are faced with more and more complex and advance operational functions which can make techniology more difficult to operate and handle. One solution to this operational difficulty is to add more automation to it, however, adding automation itself increases complexity. In addition to the increase in complexity, it is difficult to maintain operational skills in an automated environment. Those skills are precisely the ones that are most needed when the automated system is unable to handle a problem and the operator is required to intervene.Hence the focus has been with addressing the complex human-machine interaction and factors that influence successful performance. Automation solutions have often been developed without consideration of the human that needs to interact with the solution. We can provide automation that effectively solves a problem under normal conditions, but when an anomaly occurs the complexity of the automation undermines the ability of people to intervene and correct the problem. One of the goals of the ASM guidelines is to define requirements for user-centered automation and support technologies.

- OMG!! How did we got here??!

-

- What is “Abnormal Situations”

This condition is defined as an event where the process is operating outside the normal operation envelope. And if it is not bought under control though appropriate action or response, it may potentially escalate to an emergency situation where companies many have monetary or production loss or under extreme cases loss of life. For example, fire, trips, interruptions/disturbance to process, human errors or simply failing to meet the planned targets.

- What is “Abnormal Situations”

-

- What is “Abnormal Situations Management (ASM)”

ASM is a guideline that promotes effective use of existing and available resources to achieve safe and efficient operations of a process.\

- What is “Abnormal Situations Management (ASM)”

-

- Purpose of (ASM)

At the minimum ASM promotes the following ehancement.- Reduce complexity and promotes simplicity (design)

- De-cluter screen

- User centered automation

- Reduce operator mistakes/errors

- Future expansion and enhancement is manageable

- Purpose of (ASM)

- ASM in HMI

HMI that closely follow the ASM guideline will have the following characteristics.- Use a hierarchy to represent multilevel views of process.

Level 1 is generally and overview of the process that gives users an update of process status from general point of view. It typically comprise of a process KPI.

Level 2 is reserved for a particular process unit control. For example a KPI for a compressor or BMS.

Level 3 is particularly for a particular equipment in a process control. An example of Level 3 HMI display would be a graphics for a after cooler pump in a compressor - Minimal distraction

Under normal operations the HMI graphics should not be highlighted. Over using colours will prevent important process status to me loss in the mix.

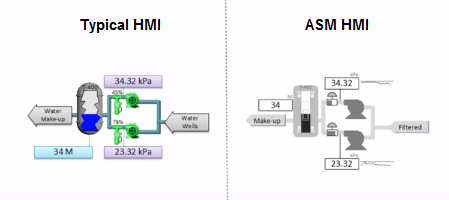

Normal operations. Everything is blended into the background and nothing stands out in the “ASM HMI” compared to the “Typical HMI” where the HMI graphics looks busy.

Alarm state. The tank high alarm stands our very prominantily in the “AS HMI Alarm” compared to the “Typical HMI Alarm” graphic.

- Contrast

Well planned and organised usage of high contrast colours to highlight what is important. The text “Lorem” can easily be found when it is highlighted in high contrast.

- Data in Context – Information

Putting data in context increases the operator’s situation awareness. Situation awareness is a deceptively simple concept. Of course the operators who run your system should be aware of its current state. But there’s much more to it than that.

Typically, an operator must go through three steps to achieve true situation awareness.- First, he must perceive important data

- Second, he must comprehend the current situation

- Third, he must predict future status

It is not enough to see current system values; the operator must see them in context to know their meaning, and then see where they are trending in order to predict what is likely to happen next.

Situation awareness does not come from a control system. “True situation awareness only exists in the mind of the human operator. Therefore presenting a ton of data will do no good unless it is successfully transmitted, absorbed, and assimilated in a timely manner by the human to form situation awareness.”

(reference Endsley) - Colours

If too much is vying for the operator’s attention at any given time, he/she won’t be able to focus on what’s important; essentially important things are drowned out by the trivial.

Color selection has to be planned carefully, because it makes the screen more complex if this pre-planning is not done in the initial stages of the design.

It is impractical for operators to memorize several colors and what they mean, however, if we limit the colour selection and put a legend for it in the HMI, it will be far more effective than just a monochrome HMI graphics.- Red for critical alarms such as shutdowns, ESD, fire and gas alarms, etc.

- Yellow for process alarms. Such as tank high alarm.

- Dark grey for status; for example, pump is running.

- Blue for abnormal state. For example, if a valve should be in auto but it is shown in manual, the valve should be highlighed in blue text colour or background colour.

- Magenta for HMI in offline status.

About 10% of males and 1 % of women are colour blind, hence avoid using colour to express operations information is ideal. However, if colours are unavoidable, proper colour selection has to be conducted.

Because peripheral vision and color blindness can be problems, make sure you distinguish the most important elements, like alarms, by more than just color. For example, give alarm level indicators different shapes as well as different colors

Flashing / blinking in the HMI is not recommended as it can triggers photosensitive epilepsy (PSE) to people with PSE. - Interactive Feedback

When an operator interacts with the system, he/she needs to know that what he/she is doing is correct and effective. This section outlines how to make an operator’s job easier by building in checks, so it is hard to make mistakes, and by making it obvious what is happening.- If the operator selects something on the screen, indicate that it is being selected with a black outline.

- If the operator initiates an action, indicate that the action is being carried out.

- Design graphics and controls so they behave consistently in all screens and do not offer surprises.

- Build in an operating range check when user input is required in the HMI system.

- Don’t be too fancy. Keep it simple

Cognitive load refers to the total amount of mental work you have to do in order to understand something. Having to remember a number of exact commands increases cognitive load; having recognizable commands or icons right in front of you reduces it.

To make it easy for operators to use an HMI, we must reduce the cognitive load required to find pertinent data, understand it, predict the future course of events, and take action. Here are some ways to make it easy.

- Use a hierarchy to represent multilevel views of process.

Reference

- Honeywell – ASM Compliant HMI Graphics Design

- Wonderware – Increased Operational Effectiveness with Situational Awareness

- Honeywell – HMI Web Graphic Best Practices

- ASM – 2009 ASM Displays GL v014

- Toward a Theory of Situation Awareness in Dynamic Systems

- Building an HMI that Works

- Setting a new standard in alarm management

- How to Improve Plant Operations through Better HMI Graphics

- Effective Automation to Improve Operator Performance